Product

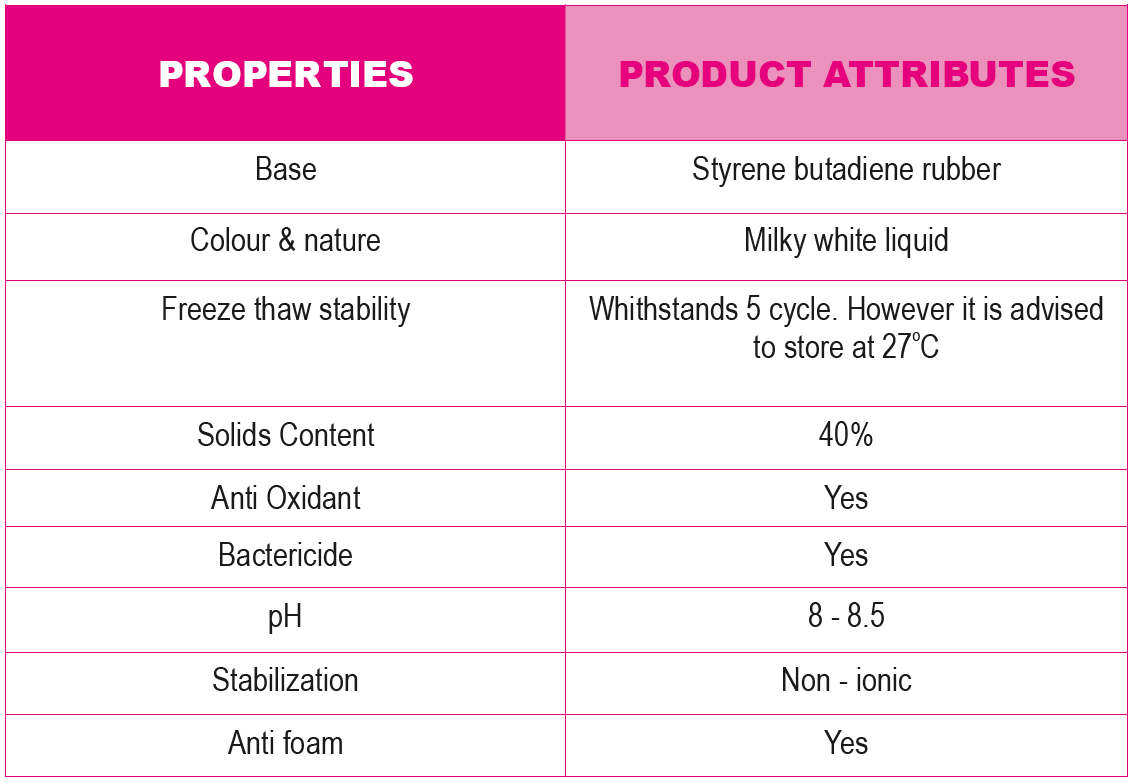

Aqua Bond Repair(ABR) is styrene butadiene rubber based milky white material. It is a multi-functional material. All kinds of cement concrete made with ABR have excellent compressive and tensile strength. ABR modified cement plaster has smooth finish and the concrete has excellent bonding and waterproofing properties.

WHERE TO USE: For water proofing terrace, water tanks. As a bonding coat for old and new construction. As floor repair mortar for chemical plants, engineering units, railway platforms etc. For repairing damaged columns and beams of structures. As passivator coat for protecting steel from corrosion.

HOW TO USE: Clean reinforcement with Aqua Rust Kleen by brush & scrub vigorously with a wire brush. Clean with a jet of water. Remove loose particles, dust and neutralize the surface. Apply passivator coat: 1 part cement, 1 part Aqua Bond Repair. Coat on cleaned reinforcement. Apply bond coat: 1 part cement, 1 part of sand, 1 part of Aqua Bond Repair on the entire surface which is to receive subsequent polymer modified mortar. Prepare polymer modified mortar: 50kg cement, 125kg zone II sand, 10 liters of water. Apply this on tacky bond coat of approx. 12.5mm of thickness per coat. Finish surface as desired using sponge, etc.

- ABR modified cement slurry has excellent adhesion and thus it joins new construction to old construction.

- It imparts flexibility to cement and thus plasters made out of ABR are crack free.

- It reduces the water demand of cement. Concrete made with ABR has excellent compressive and tensile strength.

- ABR modified cement concrete is denser and water tight.

- It is non-flammable and non-toxic and thus it is eco friendly.

- ABR modified mortar has excellent chemical resistance.

- ABR modified mortar has excellent wear and tear resistance.

Product